Cloud, Connected Data, and Confident Decision-Making

Introduction

For many small and mid-sized manufacturers, growth feels a lot like organized chaos. Orders are flowing, customers are happy, but behind the scenes, teams are juggling spreadsheets, emails, and disconnected systems just to keep production moving. It’s not that the business isn’t working. It’s that it’s working too hard.

Finance is reconciling numbers at the end of every month. Sales is checking multiple systems to see what’s in stock. Operations is manually tracking purchase orders because the ERP can’t pull real-time data. What once felt manageable now feels unsustainable. Modern manufacturing has simply outgrown the old way of working.

What used to give you an edge like experience, loyal customers, and strong processes isn’t enough anymore if the systems behind them can’t keep up. Today’s manufacturers need to move faster, make smarter decisions, and adapt instantly when supply chains shift or customer demands change.

That requires connected data, real-time visibility, and cloud-based systems that grow with you instead of holding you back.

The Old Model Is Breaking Down

Most manufacturers like you don’t start with a bad system. They start with what’s available and affordable: QuickBooks, Excel, or maybe a production tracker built in-house years ago.

It works fine when you’re small. But as the business grows, cracks begin to show.

- On-premise servers slow everything down and are expensive to maintain.

- Departments stop speaking the same data language. Finance has one version of the numbers, operations has another, and sales is caught in between.

- Decision-making gets slower because reports take too long to pull.

- Visibility disappears. You can’t see live costs, inventory, or margins, only snapshots from last week.

Disconnected systems and manual reporting can’t keep up with the speed of modern manufacturing.

The companies that are winning today aren’t just producing more. They’re seeing more. They have live dashboards tracking production, cost, and cash flow in real time. They catch inefficiencies before they become problems. And they make decisions confidently because they trust their data.

That’s what modern manufacturing looks like and it’s what we help our clients achieve every day with Acumatica ERP.

What Modern Manufacturing Actually Looks Like

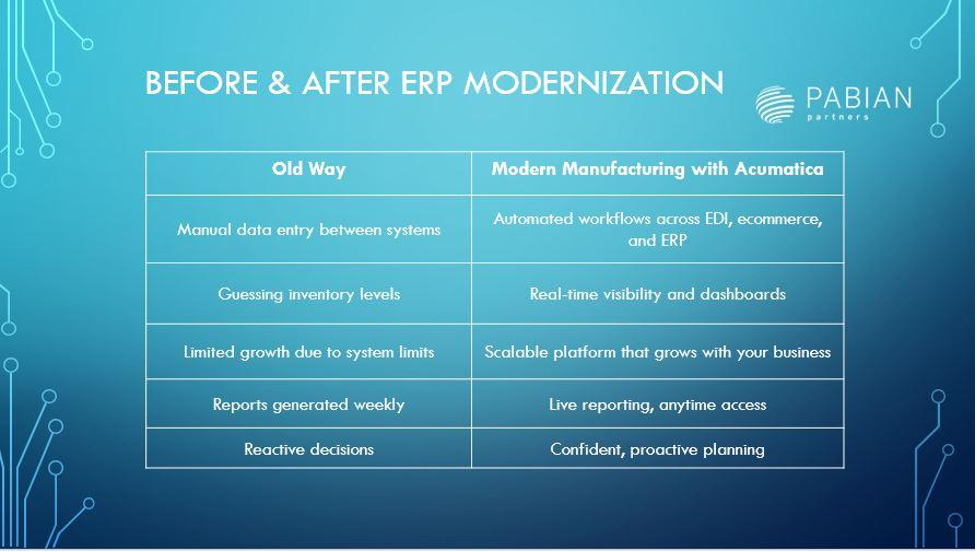

Before and After ERP Modernization

Modern manufacturing isn’t about automation for the sake of technology. It’s about visibility, agility, and confidence knowing exactly what’s happening across your business, from the shop floor to the balance sheet.

At Pabian Partners, we’ve seen how that shift happens once data starts working together instead of against you.

Take Moonlight Mixes, a gourmet snack brand that had outgrown QuickBooks and spreadsheets. Their small team was spending hours reconciling orders and manually tracking inventory. The lack of visibility made it nearly impossible to plan production efficiently.

Once they moved to Acumatica Cloud ERP, everything changed. Their order-to-cash process was automated through EDI, e-commerce, and multiple sales channels. The same team that once struggled to manage growth now handles 10 times more orders without adding admin staff.

Three years after implementation, they continue to scale confidently with accurate inventory data, automated workflows, and real-time reporting. As their CEO, Scott Waidmann, said:

“Our move to Acumatica was pivotal in our explosive growth. The system continues to impress from order processing to inventory management — and Pabian Partners made it possible.”

The transformation wasn’t just technical; it was cultural. Moonlight Mixes now operates with clarity, not chaos.

Another example is Evolution Outdoors, an innovative outdoor gear company that came to us when Sage 50 could no longer support their growing operations. They needed a more flexible platform to manage marketplaces, retail EDI partners, and scan-based trade.

We helped them transition to Acumatica, integrate with Shopify, Amazon, and other sales channels, and automate their drop-shipping operations through Rithum (formerly ChannelAdvisor).

The results speak for themselves:

- 3X revenue growth with minimal increase in staff

- True omnichannel capabilities across all sales streams

- Data-driven decisions powered by Acumatica’s built-in analytics

Their president shared that the switch didn’t just fix processes, it made the entire organization more agile. With real-time insights, they can forecast customer demand, plan smarter, and adapt quickly to market shifts.

That’s the real power of modern manufacturing: every decision backed by connected, reliable data.

The Power of Connected Data

When data lives in separate systems, every task takes longer, every report is suspect, and every decision comes with hesitation.

Connected data changes that.

With Acumatica, every department — finance, sales, production, and inventory — shares one source of truth. That means fewer errors, faster approvals, and smarter collaboration. Teams stop working in silos and start solving problems together.

Connected data also unlocks better forecasting. You can see cash flow in real time, track project profitability as it happens, and adjust production schedules before issues escalate.

For small and mid-sized manufacturers, that level of insight used to be out of reach. Today, it’s available in a browser — anytime, anywhere.

Picture your business as an ecosystem, not a collection of disconnected apps. In Acumatica, sales orders trigger purchasing, inventory updates feed finance, and customer data flows across departments automatically. That’s what connected manufacturing looks like in practice.

Why the Cloud Is the Foundation

The modern manufacturer doesn’t have time to wait for IT patches or custom reports. That’s why cloud ERP has become the foundation for growth.

With Acumatica, leaders get access to real-time data wherever they are on the production floor, in the office, or halfway across the country. Updates happen automatically. Integration with third-party tools, like CRM, e-commerce, and EDI, is built in.

The result is a platform that scales with your business instead of slowing it down. You don’t just eliminate old inefficiencies but also gain the flexibility to pursue new opportunities with confidence.

Confident Decision-Making: The Real ROI

The true ROI of modern manufacturing isn’t just about time saved or processes streamlined. It’s about confidence.

When leaders can trust their numbers, they make better decisions faster. They hire strategically, manage inventory proactively, and invest where it matters most.

That’s the shift we see every day with our clients.

They move from “reacting” to “anticipating.” From gut feeling to data clarity. From firefighting to future planning. That transformation always starts with the right foundation — a connected, cloud-based ERP built for growth.

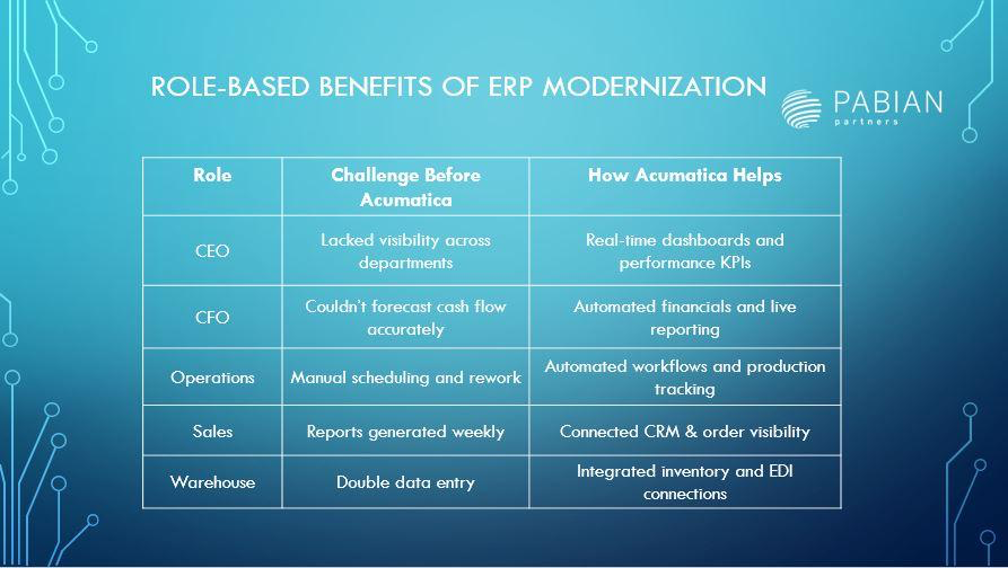

Role-Based Benefits: How Acumatica Empowers Every Team

A truly modern manufacturing platform doesn’t just help leadership; it transforms how every department works day to day. With Acumatica, everyone gains visibility, clarity, and confidence in the decisions they make.

Role-based Benefits of ERP Modernization

This is where Acumatica really shines. It creates alignment. Every team speaks the same data language, works toward the same goals, and has the tools to move faster with fewer mistakes.

Modern Manufacturing is a Mindset

Modern manufacturing isn’t just a technology upgrade. It’s a mindset.

It’s about seeing your data as an asset, not an obstacle. It’s about building systems that scale with your ambitions. And it’s about giving your team the visibility they need to perform at their best.

We are helping manufacturers and distributors build that foundation with Acumatica Cloud ERP connecting every process, every department, and every decision in one place.

Because modern manufacturing isn’t about doing more. It’s about doing better.

Ready to Modernize Your Manufacturing Operations?

Let’s start with a 30-minute discovery session. We’ll assess your current systems, identify opportunities for automation, and show you how Acumatica can bring your operations together under one connected platform.

FAQs

1. What does modern manufacturing mean for small and mid-sized businesses?

Modern manufacturing means using connected, cloud-based systems to unify operations, finance, inventory, and production. For SMBs, it’s about gaining real-time visibility into costs, materials, and performance, helping teams make faster, smarter decisions without adding complexity.

2. Why should manufacturers and distributors move to cloud ERP?

Cloud ERP systems like Acumatica eliminate silos between departments, reduce manual work, and make critical data available from anywhere. They also lower IT costs, automate reporting, and scale easily as your business grows, something on-premise or legacy systems can’t deliver efficiently.

3. How does Acumatica help manufacturers improve efficiency?

Acumatica streamlines manufacturing workflows by automating order processing, managing multi-channel sales, and connecting inventory with production in real time. It helps teams reduce errors, improve scheduling accuracy, and make informed decisions backed by live dashboards and reports.

4. What results have manufacturers achieved with Pabian Partners and Acumatica?

Clients like Moonlight Mixes and Evolution Outdoors have seen transformative results. Moonlight Mixes increased order capacity by 10x without adding staff, while Evolution Outdoors tripled revenue with a lean team by integrating their ERP with marketplaces and EDI. Both gained stronger visibility, faster decision-making, and scalable systems for growth.

5. How long does it take to implement Acumatica for a manufacturing business?

Implementation timelines depend on business complexity, but many SMBs go live within 3–6 months. Pabian Partners follows a phased, hands-on approach starting with finance and operations, then expanding to production, EDI, and reporting to minimize disruption while ensuring adoption and ROI.

6. How is Acumatica different from other ERP systems?

Unlike legacy ERPs that require costly maintenance or user-based pricing, Acumatica offers a true cloud model with unlimited users, flexible integrations, and industry-specific functionality for manufacturers and distributors. It’s built to grow with your business, not limit it.

7. How can I know if my manufacturing company is ready for ERP?

If your team relies on spreadsheets, struggles with reporting delays, or uses multiple systems that don’t sync, you’ve likely outgrown your current setup. A readiness consultation with Pabian Partners can help assess where automation and integration will bring the most impact. For more details, read the full article on how to prepare your manufacturing business for ERP success.