Implementing ERP for Distribution: What to Expect

- Implementing ERP for Distribution: What to Expect

- Signs Your Distribution Business is Ready for ERP

- Typical Timeline for ERP Software Implementation for Distributors

- Acumatica Implementation Approach for Wholesale Distributors

- How Pabian Partners Reduces Project Risk and Disruption

- What Your Team Needs to Bring to the Table

- Final Thoughts: Implementation is Where ERP Succeeds or Fails

- FAQs

If you’ve never implemented ERP before, it’s easy to imagine the worst: endless meetings, overwhelmed warehouse teams, missed shipments, and a system that never quite works the way it was promised.

The reality is more nuanced.

A successful ERP for distribution implementation isn’t about flipping a switch. It’s about rolling out the right capabilities in the right order, without disrupting day-to-day operations. When done correctly, ERP becomes a relief, not a burden.

This guide walks through realistic timelines, implementation phases, and what distributors should actually expect when implementing Acumatica, especially when working with an experienced Acumatica implementation partner like Pabian Partners.

Signs Your Distribution Business is Ready for ERP

Most distributors don’t wake up one morning and decide to implement ERP. They’re pushed there by operational pressure.

You’re likely ready for ERP if:

- Inventory numbers can’t be trusted across warehouses

- Order volume has outgrown spreadsheets or legacy systems

- Sales and warehouse teams rely on manual handoffs

- Customer requests for faster fulfillment or EDI are increasing

- Finance struggles to close the books or explain margin differences

- Growth feels harder than it should

These are common signals we see during ERP readiness conversations. They usually mean the business has outgrown its tools—not its people.

If this sounds familiar, it’s worth revisiting what distribution ERP software is designed to solve and why implementation quality matters.

Before diving into timelines, it helps to revisit what distribution ERP software is designed to solve and why so many distributors outgrow spreadsheets and disconnected systems.

Typical Timeline for ERP Software Implementation for Distributors

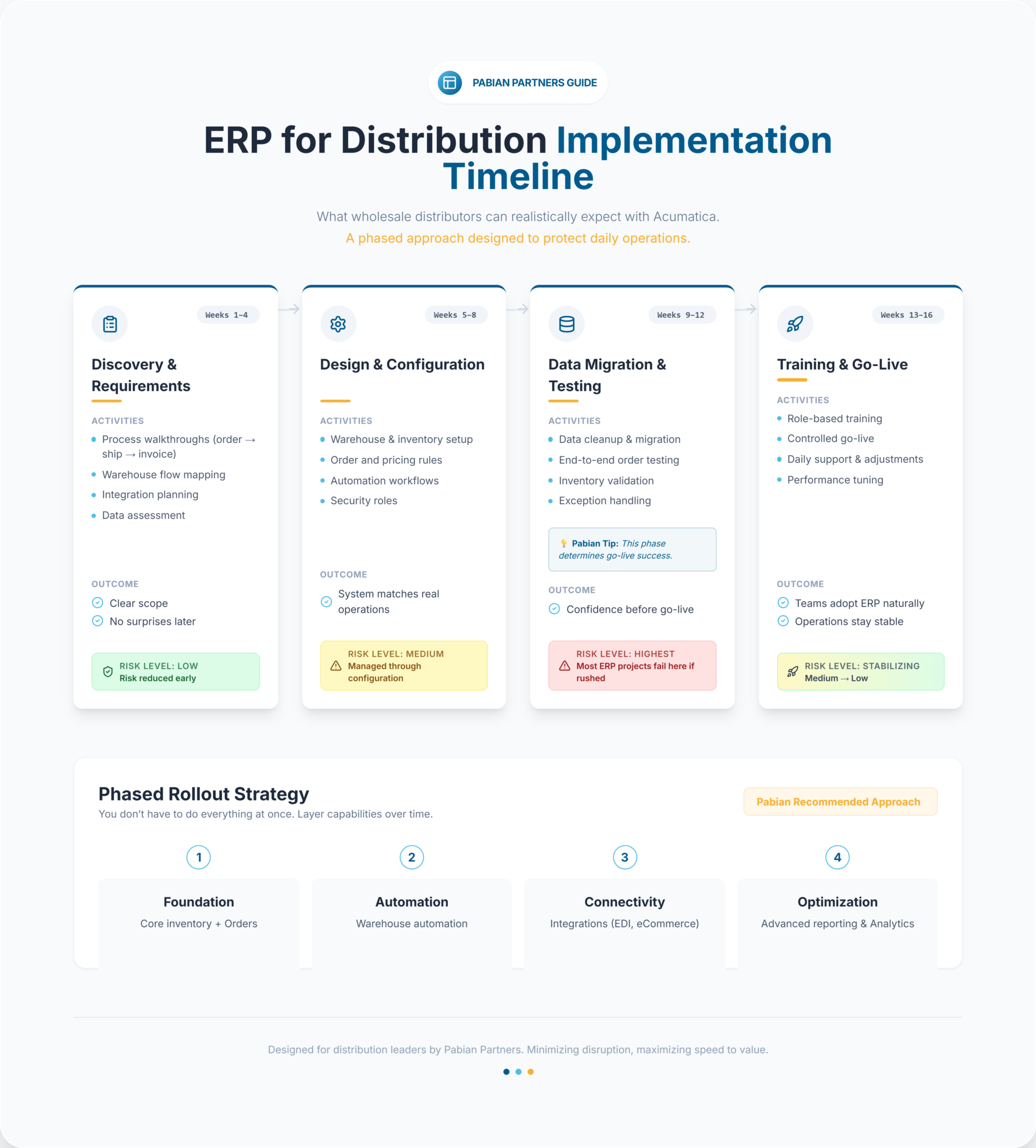

This is what a realistic ERP for distribution implementation timeline looks like when projects are phased correctly.

There’s no universal timeline for ERP projects, but there are realistic ranges.

A focused distribution ERP implementation timeline typically looks like this:

- Small to mid-sized distributors: 3–6 months

- Multi-warehouse or high-volume operations: 6–9 months

- Complex integrations (EDI, eCommerce, 3PL): Phased over 9–12 months

The key word here is phased. Trying to implement everything at once is one of the fastest ways to derail a project.

Let’s break down what actually happens in each phase.

1. Discovery & Requirements

This is the most important phase and the one that’s often rushed. During discovery, the implementation partner works with your team to understand:

- How orders flow from entry to shipment

- How inventory is received, stored, and picked

- Where manual work or bottlenecks exist

- What data needs to move from legacy systems

- Which integrations are required now vs later

At Pabian Partners, this phase is process-first, not software-first. The goal is to understand how your distribution business really operates, not how it should operate on paper.

Skipping or shortening discovery almost always leads to rework later.

2. Design & Configuration

Once requirements are clear, Acumatica is configured to support your workflows.

This includes:

- Setting up warehouses, locations, and inventory rules

- Configuring order management, pricing, and purchasing

- Defining approval workflows and automation

- Designing fulfillment logic for multi-warehouse scenarios

- Establishing roles and permissions

This is where Acumatica shines for distributors. Its flexibility allows configuration without heavy customization, which keeps the system upgrade-friendly and easier to maintain long term.

3. Data Migration and Testing

Data migration is where reality shows up.

This phase includes:

- Cleaning customers, vendors, items, and inventory data

- Importing open balances and historical records

- Validating units of measure, pricing, and costs

- Running test orders end-to-end

- Verifying inventory accuracy

Testing isn’t just for finance or IT. Warehouse users, customer service, and purchasing all need to validate workflows using real scenarios.

A strong ERP for distribution implementation treats testing as risk reduction, not a checkbox.

4. Training, Go-Live and Stabilization

Training works best when it’s practical and role-based. Instead of generic demos, effective training uses:

- Real orders

- Actual inventory

- Familiar workflows

Go-live doesn’t mean everything must be perfect. It means core operations are stable, users are confident, and support is readily available. The stabilization period after go-live is just as important as launch day. This is when refinements happen, automation is expanded, and teams start seeing the real benefits of ERP.

Acumatica Implementation Approach for Wholesale Distributors

Acumatica is particularly well-suited for wholesale distribution because it’s built around:

- Real-time inventory visibility

- Flexible warehouse workflows

- High transaction volumes

- Integration-friendly architecture

But software alone doesn’t guarantee success.

That’s why Acumatica works exclusively through certified partners. Your Acumatica implementation partner plays a critical role in how well the system supports your business.

Pabian Partners focuses on phased rollouts that prioritize:

- Core inventory and order flows

- Warehouse efficiency and accuracy

- Purchasing and replenishment automation

- Integrations (EDI, eCommerce, 3PL)

- Advanced reporting and optimization

This approach reduces disruption and delivers value early, without overwhelming teams.

How Pabian Partners Reduces Project Risk and Disruption

ERP projects fail when they feel imposed on the business instead of aligned with it.

Pabian Partners reduces risk by:

- Involving warehouse and operations teams early

- Avoiding over-customization

- Phasing complexity instead of forcing a “big bang”

- Using real data and real workflows during testing

- Staying engaged after go-live

We don’t disappear once the system is live. Stabilization, optimization, and continuous improvement are part of how we work. You are a phone call or text away from a project manager who is assigned to you from our team. We take up your burden of extra work and help cover for your team in case it’s needed.

That ongoing partnership is often what separates successful ERP implementations from ones that struggle long after launch.

What Your Team Needs to Bring to the Table

ERP success is a shared effort.

To keep your distribution ERP implementation timeline on track, your team should be prepared to:

- Assign clear internal ownership

- Participate in discovery and testing

- Clean up legacy data before migration

- Be open to process improvements

- Invest time in training

The good news? ERP usually reduces workload once the system is live. But during implementation, participation matters.

When teams are involved early, adoption happens naturally.

Final Thoughts: Implementation is Where ERP Succeeds or Fails

ERP software is powerful but implementation determines whether that power actually shows up in daily operations. Any ERP you choose, irrespective of brand name, has to be implemented by a true partner ready to deep dive into your daily operations and step up as needed.

A thoughtful ERP for distribution implementation:

- Reduces operational chaos

- Improves inventory accuracy

- Speeds up fulfillment

- Protects margins

- Supports growth without adding complexity

With the right system and the right partner, ERP becomes an enabler not a disruption.

If you’re evaluating ERP and want a realistic view of timelines, phases, and what success looks like, an experienced Acumatica partner can make all the difference.

FAQs

1) How long does ERP implementation take for a distribution company?

Most ERP for distribution implementations take 3–6 months for small to mid-sized distributors and 6–9 months for more complex, multi-warehouse operations. The timeline depends on transaction volume, integrations (EDI, eCommerce, 3PL), and how much process change is involved. Pabian Partners uses phased rollouts so distributors see value early without disrupting daily operations.

2) What slows down a distribution ERP implementation the most?

The biggest delays usually come from:

- Unclean or incomplete legacy data

- Unclear process ownership

- Trying to automate everything at once

- Limited warehouse user involvement

As an experienced Acumatica implementation partner, Pabian Partners focuses on stabilizing core workflows first, then layering in automation to keep projects on track.

3) Do we need to stop operations during ERP implementation?

No. A properly planned distribution ERP implementation timeline runs alongside your current systems until go-live. Orders still ship, warehouses still operate, and teams are trained gradually. Pabian Partners designs cutover plans carefully so go-live feels controlled—not chaotic.

4) What should distributors implement first in Acumatica?

Most distributors start with:

- Inventory management

- Order processing

- Purchasing

- Core warehouse workflows

Advanced automation, EDI, marketplaces, and analytics are typically added in later phases. This phased approach reduces risk and accelerates adoption.

5) How involved does our internal team need to be?

ERP implementation isn’t a “set it and forget it” project. Your team will need to:

- Participate in discovery and testing

- Validate real-world workflows

- Help clean and confirm data

The good news is that early involvement leads to smoother adoption and faster ROI. Pabian Partners guides teams step by step so participation doesn’t become overwhelming.

6) What role does an Acumatica implementation partner play?

Acumatica does not implement software directly. Certified partners like Pabian Partners handle:

- Requirements definition

- System configuration

- Data migration

- Training and go-live support

- Post-launch optimization

The partner you choose has a direct impact on whether your ERP system supports growth or becomes a bottleneck.

7) How much customization is required for distribution ERP?

In most cases, less than people expect. Acumatica is flexible enough to support common distribution workflows through configuration rather than heavy customization. Pabian Partners intentionally limits customization to protect system performance, upgradeability, and long-term maintainability.

8) What happens after go-live?

Go-live is the beginning, not the end. After launch, most distributors enter a stabilization phase where:

- Minor refinements are made

- Automation is expanded

- Reporting and dashboards are tuned

Pabian Partners stays engaged after go-live to ensure the system continues to evolve with the business.

9) Can ERP implementation improve warehouse adoption?

Yes — when warehouse teams are involved early. Barcode scanning, mobile picking, and real-time inventory often make daily work easier, not harder. We train warehouse users using their actual workflows, which builds confidence and buy-in quickly.

10) What’s the biggest mistake distributors make during ERP implementation?

Treating ERP as an IT project instead of an operations project. ERP touches inventory, fulfillment, purchasing, finance, and customer experience. Pabian Partners leads implementations with operations in mind, ensuring the system supports how the business actually runs.

11) Is it better to implement ERP quickly or carefully?

Carefully — but not slowly. The best implementations move fast where it’s safe and slow where it matters. A phased approach balances speed with stability, which is why it’s the preferred method for most distribution ERP projects.

12) How do we know if our ERP implementation is on track?

Clear milestones, active user testing, clean data validation, and transparent communication are key indicators. A good implementation partner will surface risks early and adjust before issues escalate. That’s how Pabian Partners keeps projects predictable and controlled.

- Implementing ERP for Distribution: What to Expect

- Signs Your Distribution Business is Ready for ERP

- Typical Timeline for ERP Software Implementation for Distributors

- Acumatica Implementation Approach for Wholesale Distributors

- How Pabian Partners Reduces Project Risk and Disruption

- What Your Team Needs to Bring to the Table

- Final Thoughts: Implementation is Where ERP Succeeds or Fails

- FAQs